Industries We Serve

Real-World Examples

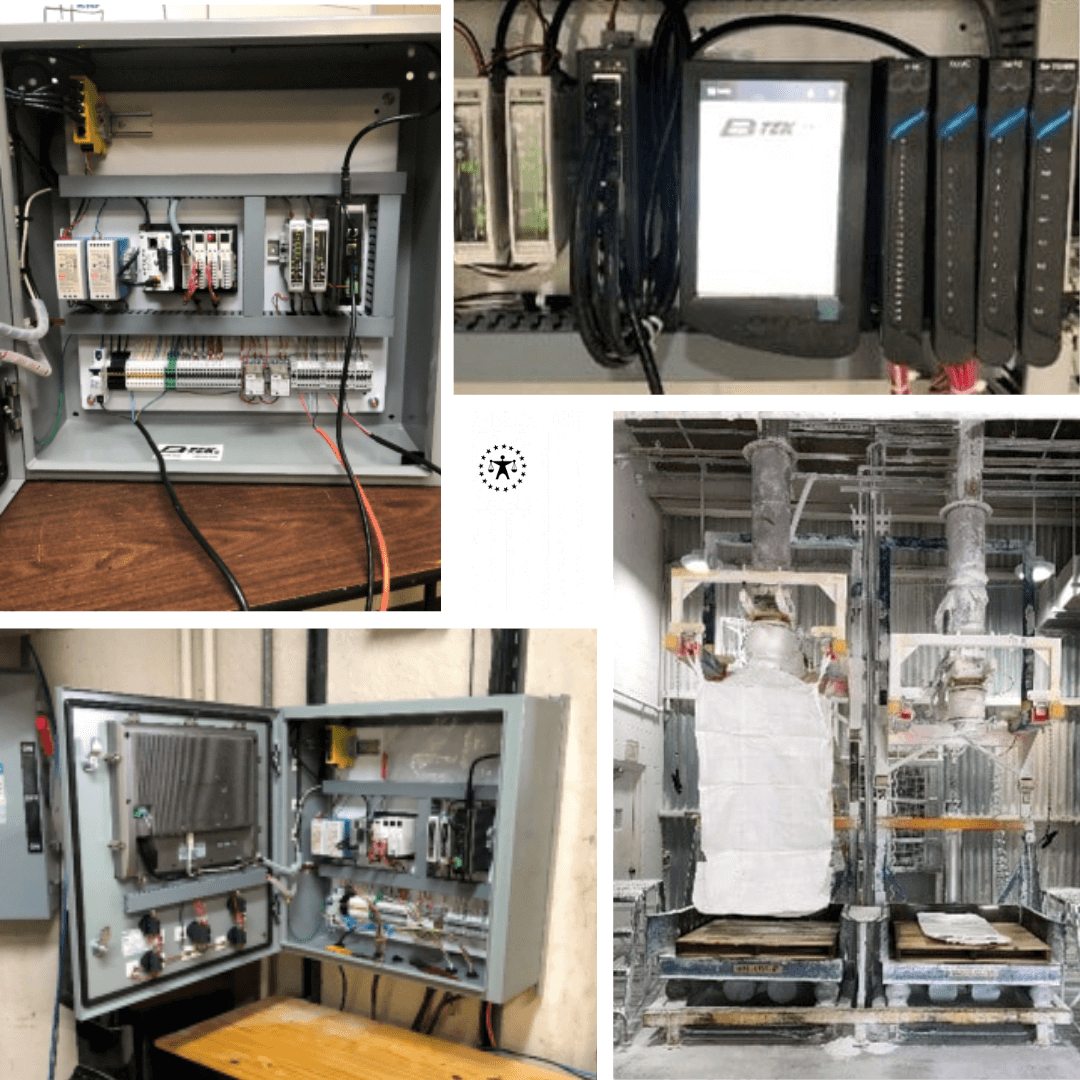

Case Study: Bulk Cement Loadout system

Brechbuhler partnered with a client to integrate a cement loadout system. Using EtherNet/IP mapping, we automated the entire filling process, improving accuracy and reducing manual oversight. The project featured:

- Logic-controlled automation via Opto 22 PAC.

- Integration with existing PLC systems.

- Custom programming for seamless operation.

Case Study: Packaging Line Automation

A client in the manufacturing sector sought to capture box weights on a moving conveyor. Our solution:

- Integrated load cells into the conveyor system.

- Automated reject arms for quality control.

- Addressed and resolved conveyor-specific challenges for uninterrupted operations.

Why Choose Brechbuhler's Engineered Solutions?

- Comprehensive Approach: We evaluate your entire process, identifying pain points and opportunities for improvement.

- Tailored Automation: Whether semi-automated or fully automated, we create solutions designed to meet your specific needs.

- Expertise Across Applications: From weight-based processes to full-scale automation, we handle the engineering so you can focus on growth.

- Ongoing Support: Our team ensures smooth commissioning and provides post-installation adjustments for optimal performance.

OUR MOTTO: TAKE CARE OF THE CUSTOMER

Loading...

Loading...