How Industrial Weighing Systems Fuel Cincinnati’s Economy and How Brechbuhler Supports It

In the greater Cincinnati region, precision weighing isn’t just a niche engineering task — it’s a backbone of industrial growth, supply-chain efficiency, and compliance assurance. If you’re an Operations VP or a Compliance Officer overseeing scale-dependent workflows, this is where smart investment in turnkey weighing solutions begins to pay dividends.

The metropolitan area around Cincinnati, OH (and the 50-mile radius that includes nearby hubs like Columbus, Dayton, Lexington, Louisville, and Indianapolis) hosts a wide array of heavy-industry operations that rely on accurate weight data, dependable equipment and robust systems. At Brechbuhler Scales, Inc. — founded in 1929 and still serving the region with full scale service, systems, rentals and calibration — we’ve been supporting local growth since day one. We were recently named Large Business of the Year by the Canton Regional Chamber of Commerce. Brechbuhler Scales, Inc.+2Brechbuhler Scales, Inc.+2

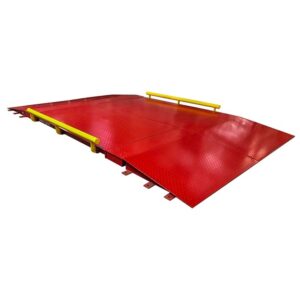

Below: examples of the heavy duty equipment in action—truck scales, floor scales, industrial platforms—reminding us that what seems like a simple flow-meter or weighbridge is actually integral to workflow reliability, data integrity and regulatory compliance.

Why Weighing Systems for Industrial Scales Matter in Cincinnati

In your role as operations leader or compliance steward, you know the drill: slowdowns cost money, non-compliance introduces risk, and inaccurate data means blind spots. Here’s how industrial scale infrastructure drives the economy locally:

- Transport/logistics throughput – Long-haul trucks, inbound/outbound freight, scrap and materials all depend on heavy-duty weighing. A certified truck scale (especially one that is NTEP-certified) ensures value, compliance and trust.

- Manufacturing & production efficiency – Floor scales, belt scales, in-motion check weighers and conveyor-integrated systems streamline throughput, reduce downtime and link weighing data into ERP/MES systems.

- Raw materials & batching – From cement to aggregates to chemical feedstocks, accurate weighing enables proper batching, less waste, fewer disputes and better margins.

- Compliance & traceability – In regulated industries (food & beverage, pharmaceuticals, chemicals, aerospace, defense) the weighing system and its software must provide data integrity, audit trails, and traceability for internal controls and external checks.

- Regional economic multiplier – When local plants and logistic hubs run smoothly, jobs remain stable, supply-chains stay competitive, and the broader regional economy benefits.

In the Cincinnati area and its nearby cities (for example: Dayton, OH; Lexington, KY; Louisville, KY; Indianapolis, IN; and Columbus, OH), the demand for industrial-grade weighing is strong. As you map the territory within 50 miles, these satellite hubs demand the same precision, uptime and systems integration you’d expect in the heart of the city.

Five Key Industries Supported by Precision Weighing

Your team may serve or oversee one (or more) of these established verticals — ones where system reliability, data integrity and heavy-duty scale integration matter most:

- Manufacturing & Metal Fabrication

Whether steel processing in northern Kentucky or machine-shop operations near Cincinnati, accurate floor- and truck-scale measurements determine cost of goods, billing, scrap yields and production throughput. - Chemical & Bulk Materials

Batch feed-stocks, weighted conveyors, automated dosing systems and in-motion check weighing: each link depends on the right weighing system for industrial scales, and the right software to log every load. - Food & Beverage / Packaging

Here the margin for error shrinks. Automated scale software must feed into check-weighing, reject circuits and traceability logs. In-motion check weighing becomes standard rather than optional. (See our solutions for check weighing and conveyor-integrated systems.) Brechbuhler Scales, Inc.+1 - Logistics & Bulk Transport

Inbound raw material truckloads, outbound product shipments, weigh-in/weigh-out processes — this is where NTEP-certified truck scales and heavy-duty scale integration become a strategic advantage. - Construction, Aggregates & Mining

Gravel, cement, sand, and recycled materials all depend on robust belt scales, vehicle weighbridges and real-time data tracking that supports operational decisions, dispute mitigation and cost control. (We know this is a speciality.) Brechbuhler Scales, Inc.+1

How Brechbuhler’s Systems Enable Growth & Efficiency

So, you’re looking at making smart decisions. Here’s how our approach supports your role and your KPIs:

- Accurate Data = Smarter Decisions

You can’t scale what you can’t measure. With weighing systems for industrial scales that provide reliable, calibrated read-outs and automated logging, you reduce human error, gain real-time insight and avoid “unknowns” that slow expansion. - Reliable Equipment = Uptime & Trust

When your production or logistics line is held up by a faulty scale? That’s wasted labor, idle trucks, and reputational risk. Our heavy-duty scale integration (including NTEP-certified truck scales) ensures the infrastructure holds up under real-world demands. Brechbuhler Scales, Inc.+1 - Automated Scale Software = Workflow Streamlining

Manual weigh-tickets, paper logs, and disconnected systems? No thanks. Our ScaleSoft and other software solutions integrate truck scale management, ticketing, ERP links and audit trail data. That means your compliance officer isn’t scrambling during audits, and your operations VP has clean dashboards. Brechbuhler Scales, Inc.+1 - Compliance Confidence

NTEP certification, 17025 calibrations, full traceability — these aren’t extras, these are must-haves. Because your business isn’t just about weighing loads — it’s about mitigating risk, maintaining traceability and passing audits with ease. NDT - Localized Support + Long-Term Commitment

Since 1929, we’ve grown alongside this region. We have a branch in West Chester, Ohio (serving the greater Cincinnati region) with service, rentals and system capability. Brechbuhler Scales, Inc. And our recent award as Large Business of the Year reflects not just equipment, but our investment in people, culture and community. Brechbuhler Scales, Inc.+1

Customer Review Snippet

“Working as Operations VP at a regional distribution manufacturing facility, we were running into multiple challenges: scale delays, manual entry errors, and audit-headaches. Since deploying Brechbuhler’s automated weighing solution — including NTEP-certified truck scales, integrated software and 24/7 local maintenance — we’ve increased throughput 18 %, reduced billing disputes by 12 %, and improved our margin by over 4 % year-over-year. Highly recommend for anyone serious about scalable, compliant weighing systems.” – VP of Operations, Bulk Materials Company (Cincinnati area)

Video / Social Integration

To see our systems in action — especially how automation, batch weighing and heavy-duty scale integration work live — check out our video overview:

Watch here (demonstrating multi-truck scale install, software integration and service lifecycle) YouTube

Final Word

If you’re managing operations in the Cincinnati metro or within 50 miles (Dayton, Lexington, Louisville, Indianapolis, Columbus) and you’re tasked with reliability, growth and compliance — then investing in weighing systems for industrial scales, automated scale software, NTEP-certified truck scales and heavy-duty scale integration isn’t optional. It’s strategic.

At Brechbuhler, we bring nearly 100 years of local expertise, a commitment to staying ahead of the curve, and full service wrap-around support (installations, calibrations, software, maintenance). You’re not just buying a scale — you’re securing the backbone of data-driven growth and efficiency.

Ready to talk through your next opportunity? Let’s measure what matters.