How Automated Weighing Systems Are Powering the Smart Factory

Automated weighing systems are revolutionizing the manufacturing landscape. They are key to the smart factory, offering precise data for better efficiency.

These systems reduce human error and boost productivity. They integrate seamlessly with IoT and AI technologies, enhancing data analysis capabilities.

Weighbridge automation is vital for industries handling large materials, like logistics and construction. It ensures accurate weight data, crucial for inventory management.

The data from these systems aids in predictive maintenance, cutting downtime and costs. They also support compliance with industry regulations, ensuring consistent weight measurements.

As technology evolves, automated weighing systems continue to offer new features, driving the digital transformation in manufacturing.

Summary

Automated weighing systems underpin smart factories by capturing precise, real-time weight data that reduces errors, improves safety, and ensures compliance. Integrated with IoT, AI, and factory data networks/ERP, they convert measurements into actionable insights for inventory control, quality assurance, and predictive maintenance. From weighbridge automation in heavy-material industries to customizable solutions across sectors, these systems raise productivity, cut costs, and speed decision-making. As Industry 4.0 advances, enhanced analytics, connectivity, and customization will further expand their impact.

The Role of Automated Weighing Systems in the Smart Factory

Automated weighing systems are fundamental to smart factory operations. They capture precise data that drives operational efficiency and quality control. By minimizing human involvement, these systems boost accuracy and reduce errors.

These systems are designed to integrate smoothly with other automation technologies. This includes IoT devices and AI-powered tools, creating a cohesive and interconnected factory environment. The integration allows for real-time data analysis and swift decision-making.

Key roles of automated weighing systems in smart factories include:

- Providing accurate and reliable weight data

- Reducing manual handling and increasing safety

- Ensuring compliance with industry standards

Through their intelligent data capture capabilities, automated weighing systems facilitate better inventory and supply chain management. The data recorded ensures that both raw materials and finished products meet consistency and quality requirements. This ability to provide crucial insights helps factory managers and engineers develop strategies that enhance productivity and optimize resource use. As industries aim for innovation, the role of automated weighing systems continues to expand and evolve.

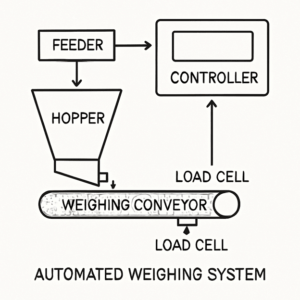

Key Components and Technologies Behind Weighing Automation

The backbone of weighing automation is a set of advanced components that work seamlessly together. Load cells serve as the core, converting physical weight into electronic signals. This data is vital for accurate processing.

Sensors play a crucial role by capturing weight information and ensuring precision. Coupled with dynamic software, these sensors enhance the system’s responsiveness. The integration of such technology facilitates real-time monitoring and control.

Key components include:

- Load cells for data conversion

- High-precision sensors

- Advanced software solutions

Modern weighing systems also incorporate wireless connectivity features. This feature enables remote monitoring, allowing managers to access and analyze data from anywhere. As technology evolves, these components continually advance, offering new capabilities and driving the innovation of smart factories further into the future.

Weighbridge Automation: Transforming Material Handling and Logistics

Weighbridge automation is a game changer in industries that manage heavy materials. It simplifies the process of weighing large shipments, thus saving time and reducing errors. These systems are essential in logistics, mining, and construction.

A fully automated weighbridge minimizes human interaction, improving safety standards. The technology reduces manual errors, enhancing efficiency and accuracy. Logistics operations greatly benefit from real-time weight data for load compliance.

Features of automated weighbridge systems include:

- Automatic vehicle identification

- Real-time data capture

- Remote monitoring capabilities

by Laurence Ziegler (https://unsplash.com/@laurenceziegler)

These advancements lead to streamlined processes and better use of resources. In turn, companies experience cost savings and enhanced performance. The results are improved logistics, reduced bottlenecks, and ultimately, a more sustainable operation.

Integrating Automated Weighing Systems With Factory Data Networks

Integrating automated weighing systems into factory data networks enhances operational capabilities. These systems work seamlessly with IoT devices and ERP software. Consequently, data flows more efficiently throughout the facility.

Such integration allows for real-time monitoring and control of weighing processes. Managers can make informed decisions based on accurate data. This connectivity supports overall factory automation and boosts efficiency.

Key integration benefits include:

- Improved data accuracy

- Enhanced decision-making speed

- Streamlined production processes

by Growtika (https://unsplash.com/@growtika)

Ultimately, this integration leads to reduced operational costs. By leveraging existing data networks, factories can optimize resource allocation. As a result, companies experience improved production and greater competitive advantage.

From Data Capture to Actionable Insights: Enabling Data-Driven Decision-Making

Automated weighing systems capture precise and real-time data. This data is crucial for enhancing manufacturing operations. When paired with advanced analytics, it transforms into valuable insights.

These insights enable businesses to make smarter decisions. Automated systems identify trends and patterns easily. Factory managers can optimize processes based on these insights.

Key advantages of leveraging data include:

- Improved inventory management

- Enhanced quality control measures

- Timely predictive maintenance

Data-driven decision-making leads to increased efficiency. It minimizes waste and enhances resource utilization. By utilizing this approach, companies achieve a competitive edge in the market. Decision-makers gain confidence in their strategic choices. Ultimately, the smart use of data propels businesses forward in the digital age.

Benefits of Automated Weighing Systems for Manufacturing Efficiency

Automated weighing systems are revolutionizing manufacturing by boosting efficiency. These systems streamline operations and minimize human errors. Consequently, this leads to more accurate and consistent production outcomes.

Implementing such technology reduces manual labor costs. This allows resources to be reallocated to more strategic tasks. The result is a more agile and adaptable production line.

Additional benefits include:

- Reduced material waste

- Enhanced process speed

- Improved safety conditions

As companies adopt automated weighing solutions, they witness significant cost savings. The reduced need for rework enhances overall productivity. Ultimately, these systems play a vital role in achieving seamless and efficient manufacturing environments. Businesses that embrace these technologies gain a competitive advantage.

Industry Applications and Customization Options

Automated weighing systems cater to diverse industry needs. From food processing to pharmaceuticals, each sector benefits uniquely. These systems offer flexibility and adaptability, providing tailored solutions for specific applications. Customization ensures precise integration with existing workflows.

Common industry applications include:

- Inventory management

- Quality control

- Regulatory compliance

Customization options extend beyond standard features. Companies can integrate with ERP systems for seamless data exchange. This allows businesses to optimize operations and achieve specific goals. Such versatility makes automated weighing essential across various industries. As technology advances, these systems continue to evolve, meeting ever-changing industrial demands.

Future Trends: The Evolution of Weighing Automation in Industry 4.0

The future of weighing automation is bright and ever-evolving. Industry 4.0 paves the way for revolutionary changes. Key trends shaping this evolution include:

- IoT and AI integration

- Enhanced data analytics

- Increased customization options

These innovations promise greater efficiency and accuracy. Companies are adapting quickly to remain competitive. As technology advances, automated weighing systems will offer even more capabilities. Businesses that embrace these trends will lead the way. The journey towards smarter factories is well underway.

Conclusion: Embracing Automation for a Smarter Factory

Embracing automated weighing systems is crucial for smart factory evolution. These systems enhance efficiency and accuracy in manufacturing. They empower data-driven decisions for greater operational control.

As automation continues to advance, factories will see significant gains. Those ready to integrate these technologies will reap immense benefits. The future of manufacturing lies in smart automation.

Q&A

Question: What role do automated weighing systems play in a smart factory?

Short answer: They act as a foundational data source, capturing precise, real-time weight measurements that drive efficiency, quality, and safety. By minimizing manual handling, they reduce human error and improve consistency. Their seamless integration with IoT devices and AI tools enables on-the-spot analysis and faster decision-making, supporting inventory control, quality assurance, predictive maintenance, and regulatory compliance across the factory.

Question: Which components and technologies make accurate automated weighing possible?

Short answer: Core components include load cells that convert physical weight into electronic signals, high-precision sensors that ensure accuracy, and advanced software that processes, analyzes, and controls weighing operations. Modern systems also feature wireless connectivity for remote monitoring and real-time oversight. Together, these elements deliver responsive, reliable measurements that can be fed into broader factory systems.

Question: How does weighbridge automation transform logistics and heavy-material industries?

Short answer: Automated weighbridges streamline the weighing of large shipments by reducing manual steps, improving safety, and delivering accurate, real-time data for load compliance. Features like automatic vehicle identification, continuous data capture, and remote monitoring cut errors and delays, leading to smoother logistics, fewer bottlenecks, better resource utilization, and measurable cost savings in sectors like logistics, mining, and construction.

Question: How does integration with factory data networks, IoT, and ERP turn data into actionable insights?

Short answer: Integration enables weight data to flow instantly across connected systems, where analytics can detect trends and anomalies. This connectivity supports real-time monitoring and control, powering use cases such as inventory optimization, tighter quality control, and timely predictive maintenance. The result is faster, more confident decision-making and streamlined production processes that lower operational costs.

Question: What tangible benefits can manufacturers expect from implementing automated weighing systems?

Short answer: Manufacturers see fewer errors, reduced material waste, faster processes, and improved safety due to less manual handling. Labor can be reallocated to higher-value tasks, boosting agility and productivity. Consistent, compliant measurements and better data visibility lead to cost savings, higher product consistency, and a stronger competitive position as Industry 4.0 capabilities expand.