Truck Scale Calibration in Northern Illinois

If you operate a truck scale in Northern Illinois, calibration isn’t optional—it’s operational hygiene. Accuracy, compliance, and revenue protection all hinge on it. Yet many facilities still blur the line between calibration, testing, and repair, assuming a scale that “looks fine” is good enough.

In regions like North Aurora, IL, that assumption gets expensive—fast.

Between heavy truck traffic, strict Illinois oversight, and Midwest weather extremes, truck scales take constant abuse. Understanding what certified calibration actually involves—and how often it’s truly needed—keeps you ahead of inspectors, auditors, and customer disputes.

Why Truck Scale Calibration Matters

Truck scale calibration ensures the weight your scale displays matches the actual weight on the deck—within legally allowed tolerance. When it doesn’t, the ripple effects show up across operations.

Poorly calibrated scales can cause:

- Regulatory violations during Illinois inspections

- Revenue leakage from under-weighing outbound loads

- Customer disputes when tickets don’t reconcile

- Audit failures due to missing or expired certificates

- Operational slowdowns from reweighs and rejected loads

In short, inaccurate scales quietly erode trust and margins. Certified calibration protects both.

This is why truck scale calibration in North Aurora, IL and broader scale calibration in Illinois remains one of the most critical compliance services for commercial operators.

Calibration vs. Testing vs. Repair (Plain English)

These terms are often used interchangeably. Inspectors don’t.

Scale Testing

A test checks whether the scale is accurate at that moment. No adjustments. No certification. Think snapshot, not solution.

Scale Calibration

Calibration verifies accuracy and performs adjustments to bring the scale back within legal tolerance. This process produces a certified truck scale calibration—the documentation inspectors expect.

Scale Repair

Repair fixes broken or failing components such as load cells, junction boxes, wiring, or foundations. Repairs may be required before calibration can occur.

Bottom line:

- Testing identifies a problem

- Repair fixes damaged components

- Calibration makes the scale legally accurate again

For compliance, calibration is the must-have.

How Often Should You Calibrate a Truck Scale in Illinois?

At minimum, once per year.

In real-world Northern Illinois conditions, that’s often not enough.

Facilities may need more frequent calibration due to:

- High truck volume or impact loading

- Aggregate, recycling, or agricultural operations

- Seasonal freeze/thaw cycles

- Foundation or approach settlement

- Large temperature swings

Many commercial sites schedule biannual or quarterly calibration, especially before peak production seasons or anticipated inspections.

If your scale is an NTEP truck scale, maintaining calibration is essential to remain compliant with Illinois regulations and NTEP performance standards.

What a Professional Calibration Visit Includes

A proper calibration is not a quick drive-by. A professional visit typically includes:

- Certified test trucks or test weights traceable to national standards

- Section testing across the full deck

- Cornering tests to verify load distribution accuracy

- Zero and balance verification

- Mechanical and electronic adjustments

- Final tolerance confirmation per Illinois specifications

- Official calibration certificates and documentation

If adjustments aren’t made, it wasn’t a calibration—it was a test.

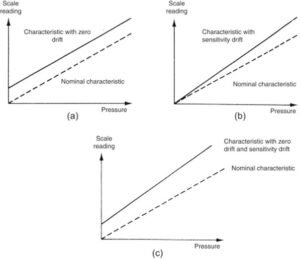

Why Midwest Truck Scales Drift Out of Calibration

Northern Illinois is hard on infrastructure, and truck scales feel it first.

Common causes of drift include:

- Freeze/thaw cycles shifting foundations

- Water intrusion into load cells or junction boxes

- Approach or pit settlement

- Debris buildup beneath the scale

- Load cell fatigue from heavy impact traffic

- Temperature-driven electronic variation

This is why a scale that passed last year can quietly fall out of tolerance long before the next inspection.

Documentation Inspectors Expect to See

Accuracy alone isn’t enough. Inspectors expect documentation to back it up.

You should maintain:

- Current calibration certificates

- Historical calibration records

- Test weight traceability documentation

- Repair and adjustment logs

- Tolerance verification reports

Missing or outdated paperwork can result in citations—even if the scale weighs correctly on inspection day.

Signs Your Scale Needs Calibration Sooner Than Scheduled

Don’t wait for a failed inspection. Warning signs include:

- Repeat weigh tickets don’t match known loads

- Inconsistent reweighs of the same truck

- Unexpected zero balance changes

- Driver or customer complaints

- Seasonal accuracy shifts

- Failed repeatability or section tests

If these show up, it’s time for commercial scale calibration, not a quick check.

Truck Scale Calibration Services in North Aurora, IL

Facilities across Northern Illinois depend on accurate truck scales to keep materials moving and margins protected. In and around North Aurora, calibrated scales support:

- Aggregate and construction materials

- Recycling and waste operations

- Agriculture and grain handling

- Logistics, freight, and distribution

Scheduling calibration ahead of peak season—or ahead of inspection windows—reduces downtime, avoids last-minute scrambles, and keeps operations compliant.

If you’re running a commercial truck scale in Northern Illinois, certified calibration isn’t optional. It’s the cost of accuracy—and the smart way to protect compliance, credibility, and revenue.